SL90

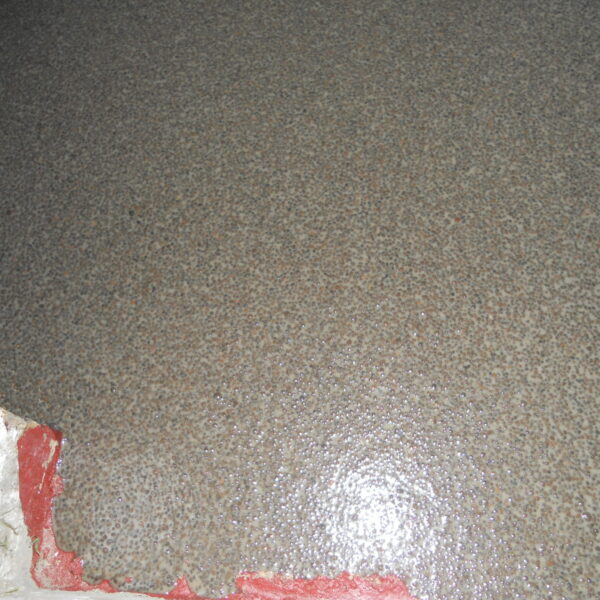

SIRN SL90 is not just a single product, but a complete line of cementitious self-levelling compounds, specifically designed for the naval sector.

They can be used as a substrate for leveling sheet metal or as a smoothing compound before installing carpet, vinyl, rubber, tiles.

Equipped with MED certification, they all boast an exceptional adhesion capacity to metal sheets, thanks to SIRN Primer Semtex T1.

Based on specific needs, it is always possible to choose the correct density, between:

0.9kg/dm³ – 1.1kg/dm³ – 1.6kg/dm³.

Over the last 10 years, several tens of thousands of square meters of SL90 have been applied on cruise ships of the most important shipping companies in the world.

SIRN ST100

SIRN ST100 is a lightweight underlay, designed to be applied in areas intended to be covered with ceramic tiles, granite or marble, or, once smoothed with SIRN SL90, with carpet and vinyl.

SIRN ST100 has an adhesion guaranteed by the SIRN PRIMER SEMTEX T1, and is made up of the correct ratio of cement, selected aggregates and latex.

The subfloor is laid using brackets, in order to ensure the desired height, and then smoothed and compacted using a spatula. The thickness can reach up to 50 mm per laying coat.

SIRN ST100 has over 20 years of applications on every type of ship for thousands of metres, where it has demonstrated its formidable characteristics, and today it is an undisputed benchmark for the MED certified naval underlayment market.

SIRN SP50

SIRN SP50 is a lightweight underlayment designed to thermally insulate the environment, preventing the sheet metal from transmitting low or high temperatures inside the ship.

SIRN SP 50 has adhesion to the sheet metal guaranteed by SIRN PRIMER SEMTEX T1, and is made up of the correct mixing of SIRN SL90 and the aggregate SIRN Fein. The aggregate is appropriately prepared in the factory, so as to bond appropriately and uniformly to the cement paste.

SIRN SP50 is a trowelable product, which tends to self-level.

To highlight its thermal characteristics, it requires a thickness between 12 and 20 mm.

Given its composition, before receiving any coating it is best to apply a pure smoothing of SIRN SL90.

With over 20 years of applications on board every type of vessel, the SIRN SP50 has proven its reliability around the world.

The product is MED Certified.

SIRN VISCOGREEN

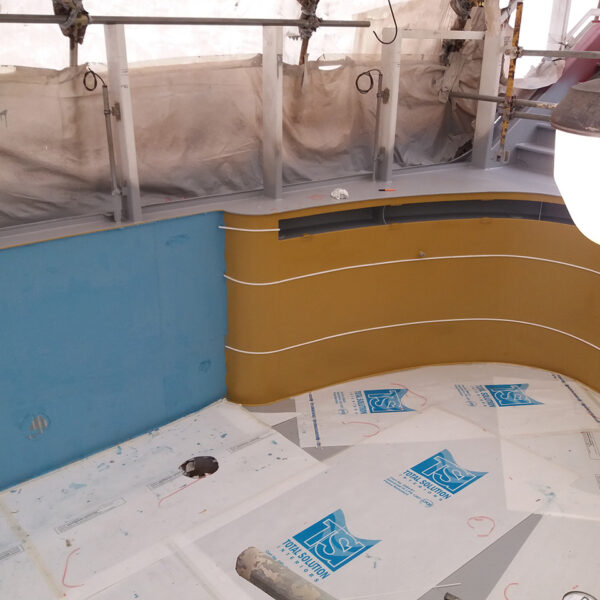

SIRN VISCOGREEN is a high performance two-component viscoelastic polyurethane resin.

It was developed to reduce low-frequency vibrations that are transmitted through the sheets of the hull or bulkheads (structural noise), generated by thrusters, engines, electric generators, compressors and various systems in the engine room.

SIRN VISCOGREEN is light – only 1.3kg/dm3 – and is applied using a toothed spatula directly on the sheets, in a thickness of 1 or 2 mm. In order to work, the visco must be forced by another layer of different material: once blocked by this, it can convert vibrations into heat.

SIRN VISCOGREEN can be forced with:

1. Steel plates of thicknesses from 1 to 3 mm covering approximately 85% of the bridge surface.

It is possible to carry out the application vertically, so as to also treat the hull and bulkheads.

2. Sottofondi. Sono disponibili due alternative:

- Uno strato di SIRN SL90 tra gli 8 ed I 15 mm

- Uno strato di SIRN ST100 tra gli 8 ed I 30 mm

SIRN VISCOGREEN è un prodotto interamente Made in Italy, poiché è stato studiato nei I nostri laboratori e testato nelle sue performance presso l’Università di Genova e il Cetena.

Negli anni, SIRN VISCOGREEN è stato applicato in varie configurazioni in lussuose navi da crociera, mega yachts, pleasure yachts, traghetti e su varie navi mercantili.

Il prodotto è certificato MED.

SIRN VISCOBOX

SIRN VISCOBOX is a modular system in the shape of boxes, welded to the bulkheads or to the top of the bridges with the aim of reducing structural vibrations, which would otherwise propagate.

SIRN VISCOBOX is composed of a C-shaped galvanized sheet metal with a thickness of 1.5mm, filled with SIRN VISCOGREEN. A J-shaped blade, also in galvanized steel, is immersed inside. The external part of the blade is prepared with teeth, which will be welded to the bulkhead.

They are usually applied to the external bulkheads in the area of the mooring winches.

SIRN VISCOBOX is proposed, as standard, in a length of 1000 mm. The cassettes can then be cut to the length required by the application area. They are then welded in parallel rows, spaced 450-500 mm apart.

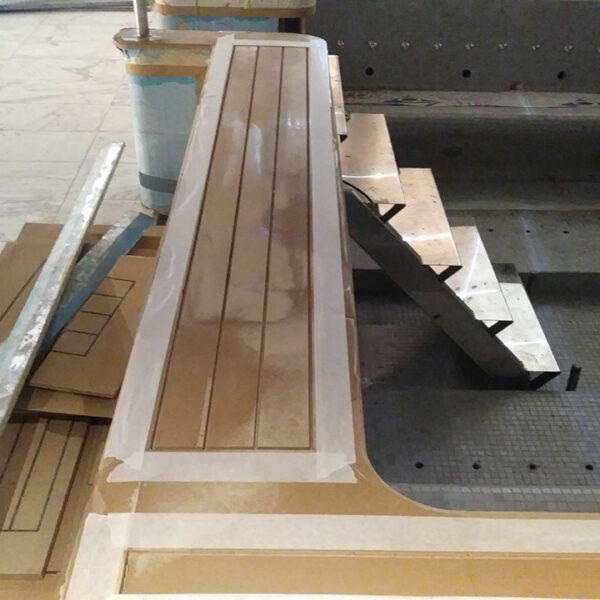

SIRN LITOFLOOR STEEL

SIRN LITOFLOOR STEEL is a multilayer acoustic floating floor, designed to reduce acoustic noise and thus guarantee greater on-board comfort.

Thanks to the use in the layers of SIRN VISCOGREEN, this floating floor also has exceptional results in reducing low frequency vibrations, which can be transmitted through the deck and hull plates.

The system is composed of:

- A layer of SIRN VISCOGREEN of approximately 1 mm

- A layer with a sublayer, such as SIRN ST100 or SIRN SL90, of approximately 10 mm.

With this cement layer it is also possible to fill and level the deformations of the metal sheets, thus presenting a flat surface that will allow correct installation of the subsequent layers. - A layer with rock wool panels with a density of 140-150kg/m3

- A layer of 2 mm thick steel plates, spot welded.

- Another layer of SIRN VISCOGREEN, to ensure the bonding of the sandwich made up of the plates

- One layer of 3mm thick steel plates.

Once SIRN LITOFLOOR STEEL has been completed, it is possible to perform a final smoothing with the polyurethane resin RESISIRN and receive the final covering (carpet, PVC, vinyl and more).

SIRN LITOFLOOR STEEL is the technical solution to the need to reduce significant airborne and structural vibrations.

The system is MED certified in Class A and has great success in the cruise sector as well as in that of mega yachts.

Upon request, SIRN also supplies rock wool packaged with SIRN PROTECT PW, also MED certified.

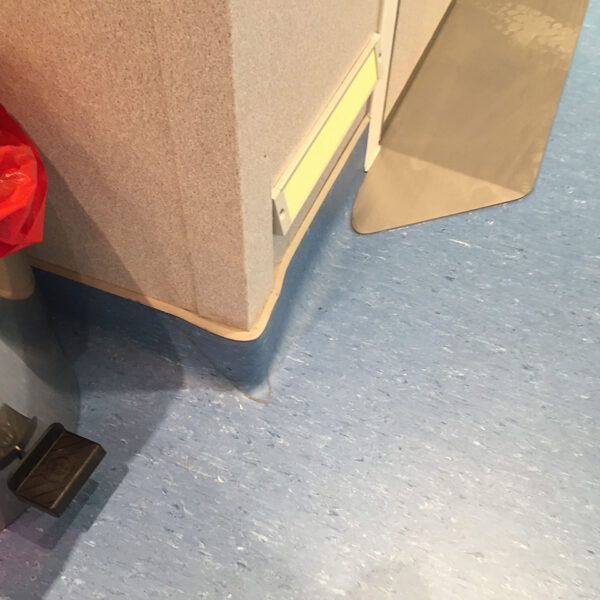

RESISIRN

RESISIRN is a high-performance two-component polyurethane resin, developed for application as an internal and external substrate.

It is a self-levelling and particularly elastic product, available in a wide range of colours.

RESISIRN has a density of 1.2 Kg/dm³.

Before installation, the sheet metal must be prepared and covered with a coat of SIRN Epoxy Primer.

- RESISIRN C, for substrates with a thickness between 10 and 30 mm

- RESISIRN G, for substrates with noise reduction characteristics, in particular from foot traffic

- RESISIRN Tixo, for vertical applications.

The system can be completed with RESISIRN Finish, used as a polyurethane protective film, with excellent resistance properties to chemicals and abrasion; this can be supplied transparent or in a color of your choice.

SIRN ELASTIC T

SIRN ELASTIK T is a two-component, high-performance polyurethane adhesive, formulated for bonding ceramic tiles and stone material to absorbent and non-absorbent substrates.

SIRN ELASTIK T is easy to work with, is extremely strong and has high flexibility. When used vertically it does not drip, and allows the adhesion of large format tiles without any slipping.

The indicative consumption ranges from 2.5 to 3.5 Kg/m² depending on the support and the type of notched trowel used (size n.4 or n.5)

SIRN ELASTIK T is MED certified and has been widely used for thousands of square metres on board the most prestigious cruise ships.

ADESIRN

ADESIRN is an acrylic adhesive in water dispersion, simple to spread, ideal for bonding floors – vinyl, linoleum, rubber, carpet – to all absorbent or poorly absorbent substrates in indoor environments.

The indicative consumption ranges from 0.25 to 0.5 Kg/m² depending on the uniformity of the substrate, the back of the covering and the trowel used.

With limited aptitude for flame spread, ADESIRN is MED certified and boasts exceptional bonding capacity. It does not contain toxic substances: it can be stored without any particular precautions and does not present any risk to health.

Over the last 10 years, ADESIRN has been adopted as a vinyl glue on many hospitals on cruise ships of the most important shipping companies in the world.